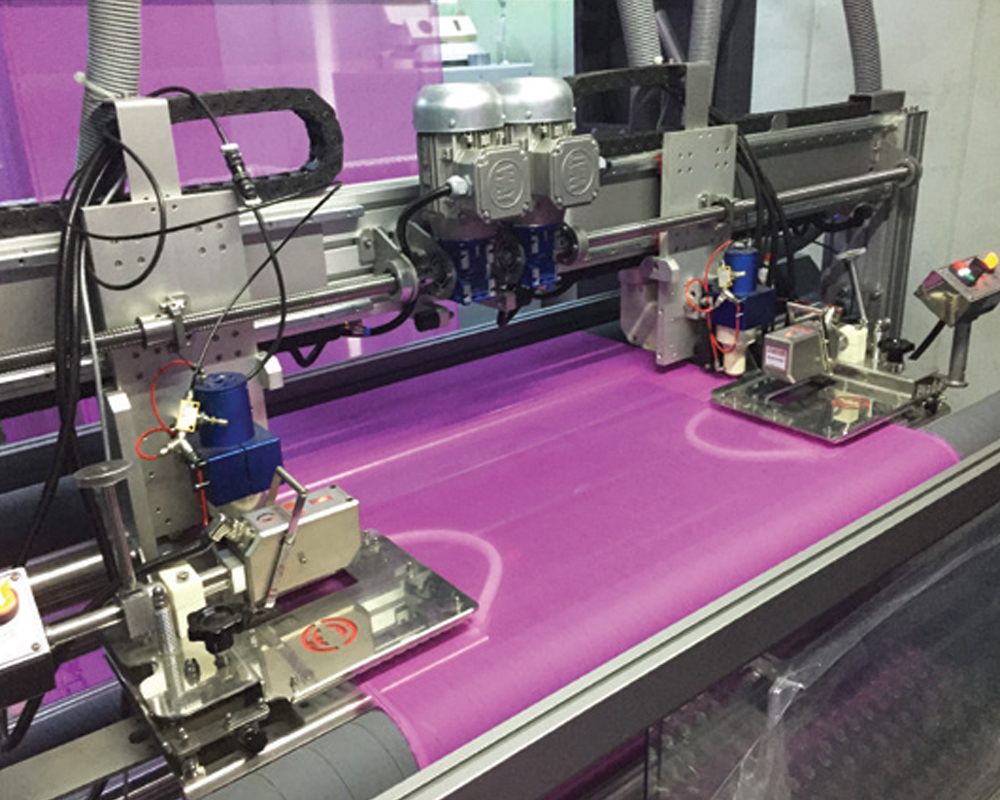

The unit is specially designed and preferred for edge trimming processes of polyester fabrics. Edge fibers of polyester fabrics are strengthened and edge fibrillation is prevented thanks to the ultrasonic edge trimming technology.

According to the desired speed and production capacity, alternative ultrasonic heads and transformers can be provided.