Stenter and drying processes in a single machine if required, in addition to the fabric preparation leveling chain, the fabric width adjustment can be made with the chain system in the chamber the first pass of the fabric, the width adjustment system available in each chambers, the air speeds can be controlled independently in the lower and upper nozzle groups, energy efficient class IE4 type fan motos provides optimum energy consumption values, homogeneous heat distribution and balanced drying capacity thanks to its cross-positioned fan and nozzle structure, increased drying and tumbler effect with its motorized distance-adjusted nozzle structure, Preventing color changes with the by-pass system feature available in all chambers, lower production costs, better shrinkage and fabric hand feel gain.

HYBET

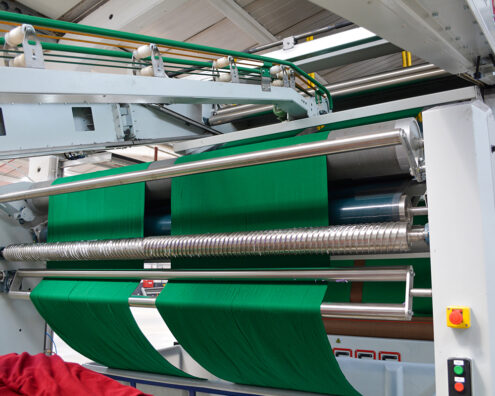

Combi Relax Dryer

FOR OPTIMIZED

RESULTS

INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY