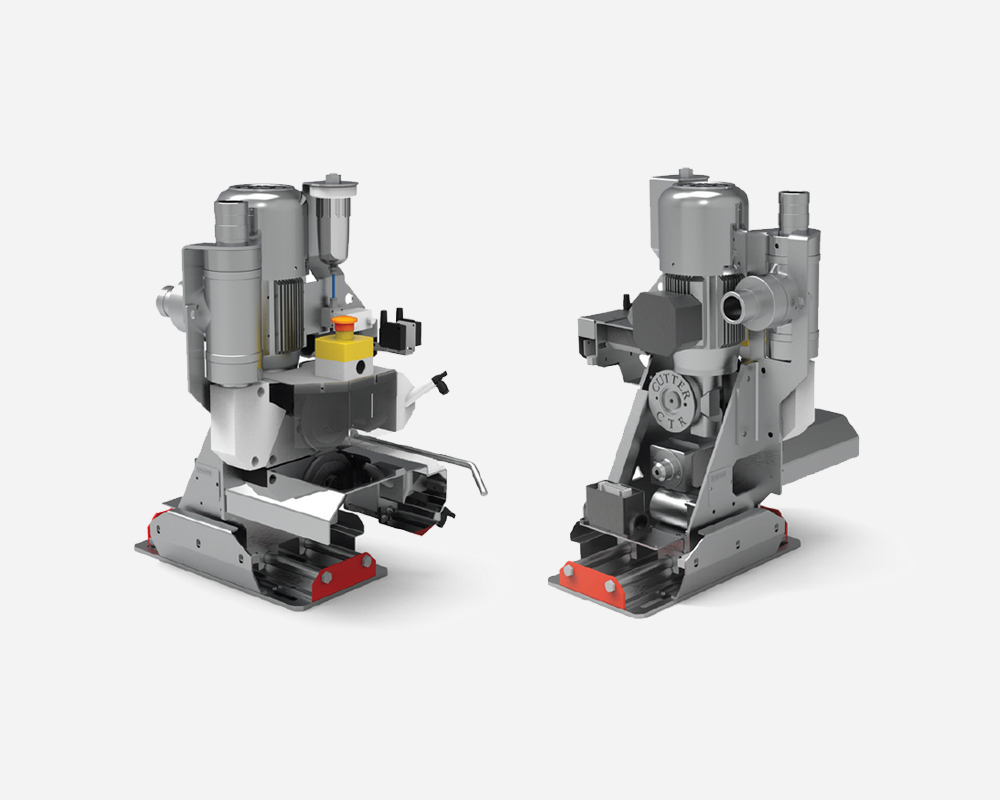

The unit is designed and produced to enable trimming fabric edges as desired on exit chain rails of stenter, compactor and dryer machines.

Whether gum application done or not, trimming unit follows the fabric edge with photocell sensor and edge trimming is done according to the pinning level. The unit works with synchronization of chain speed or independently.

Edge trimming process is being done while fabric left the chain rails in order to have smooth trimming fabric surface and to avoid any damage cause by fabric wastage. Edge trimming wastage success up to 6-8 mm (without edge gum application), 10-12 mm fabric edge wastage (with gum application).