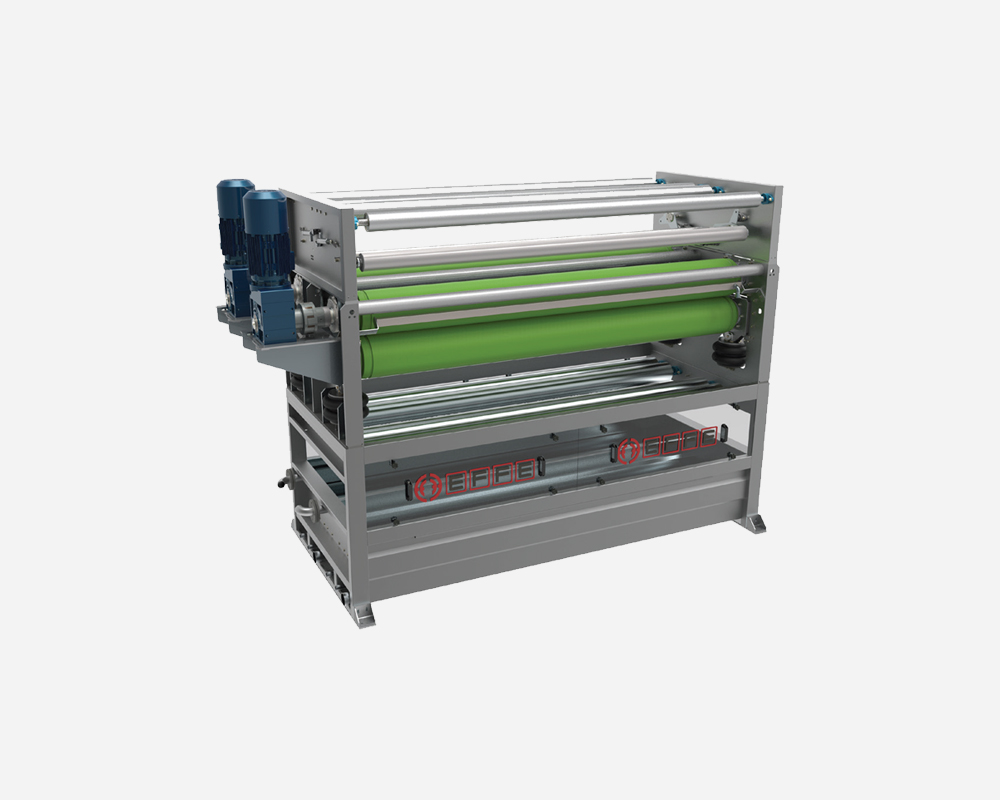

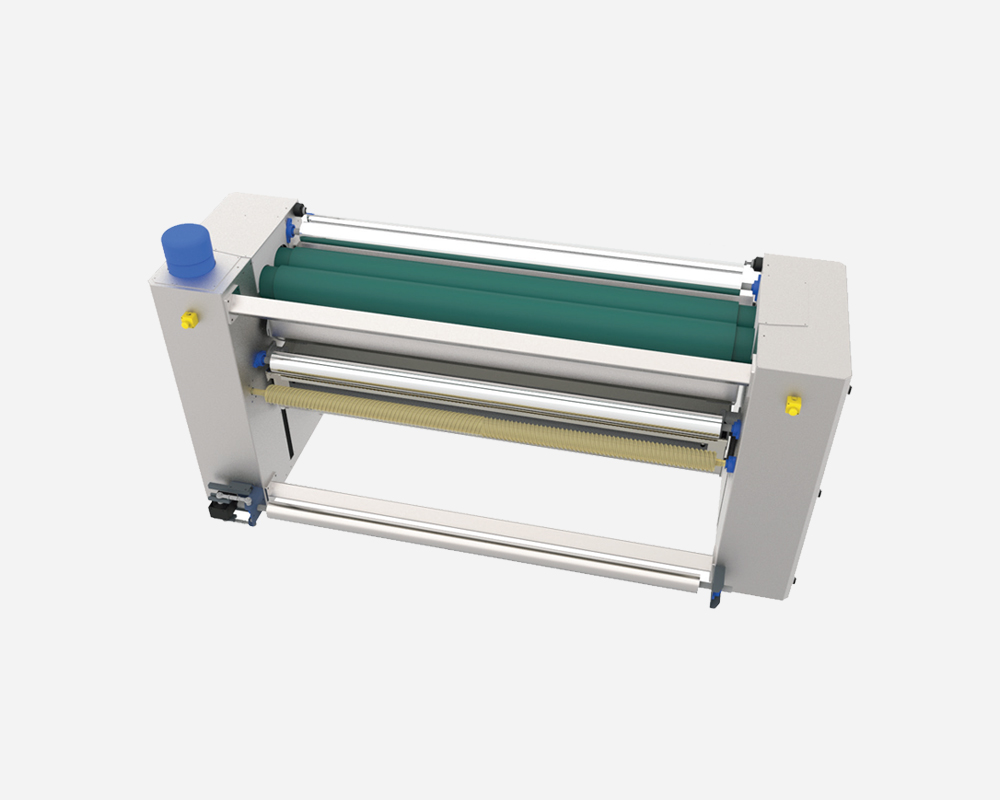

This unit is designed to be used prior to stenter machines especially in home textile manufacturing plants. Unit is used to make finishing processes by shrinking the knitted and woven fabrics in the heated pre-wash tank.

PRE-WASHING UNIT

EF-WU

INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY