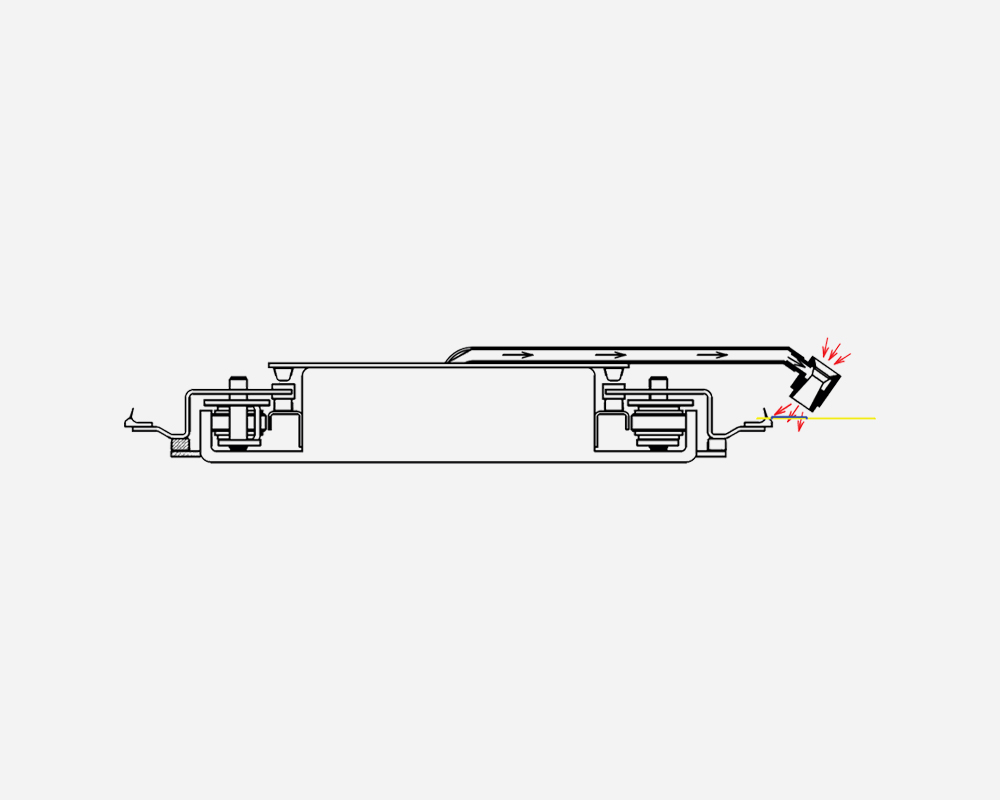

At the last chamber, current hot air pressure in the chamber gets increased by the unit mounted on right and left sides of the rails. Pressure increased hot air is used as close system and gets blowed to gummed fabric edges. Hot air that dries fabric edges stays in the chamber so no extra costs occur. Thanks to this unit, machine production speed stays stable on edge gumming process. Gained energy saving and increased production capacity make the user competetive.

CHAMBER BUILT - IN EDGE DRAYING UNIT

EF-EDU/CI

INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY — INNOVATIVE PRODUCTION FOR TEXTILE INDUSTRY