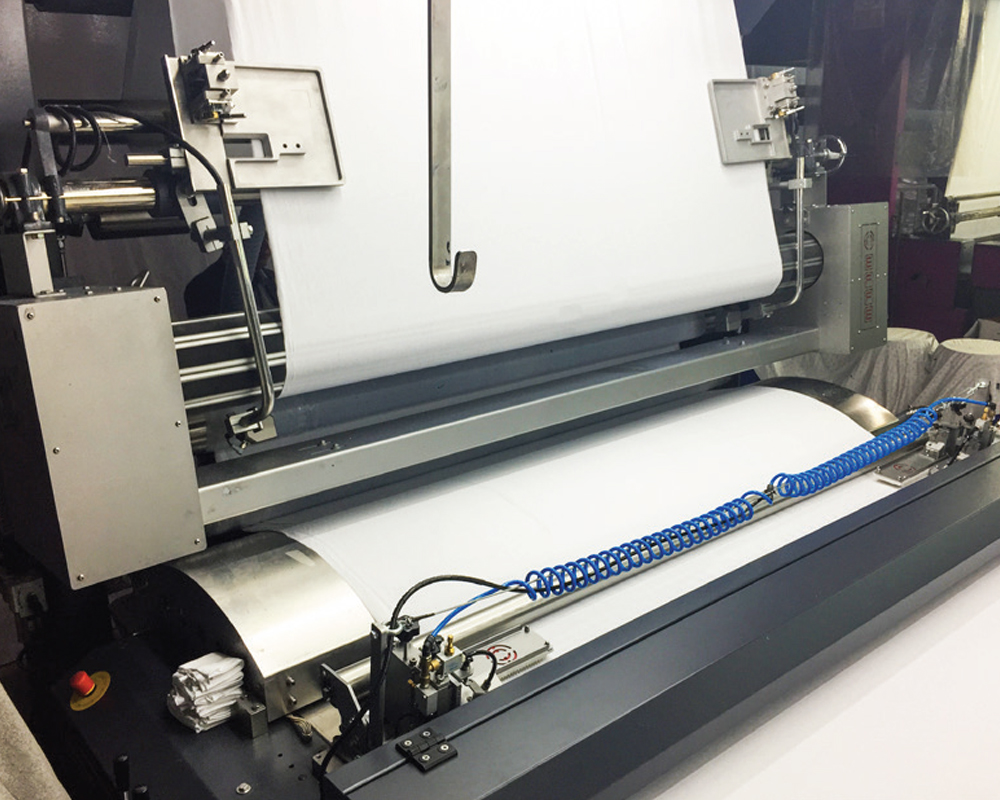

Fabric edge curls adversely effects printing quality and cause increase of fabric wastage. Thanks to the pneumatic spreader unit which is placed prior to the pressure roller where the fabric completely fixes on machine’s blanket, both edge of fabric can be un-curled with success.

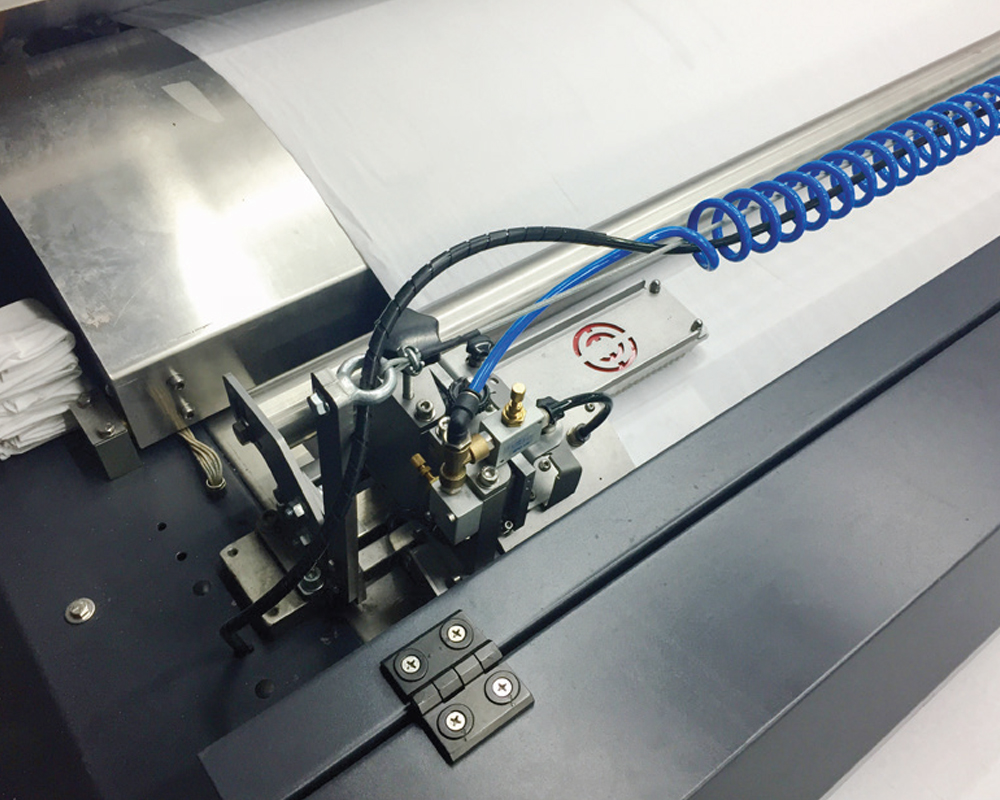

Pneumatic edge spreader unit is equipped with special nozzle system that provides compressed air to decurl fabric edges. The unit uses plant compressed air. If compressed air is not required, the unit can be used without compressed air. Spreader units that placed on sides of stainless profiles can be adjusted according to the fabric width separately